To begin the production of my books I had to print my content, this was done digitally to be consistent together. After that was done, I had to print the covers in the appropriate print method. First I screen printed.

After that was finished I completed my lino-printing. I did this with magenta ink and after a test on paper it was a very bright and vibrant magenta when wet, however I found when it dried it turned out a lot darker.

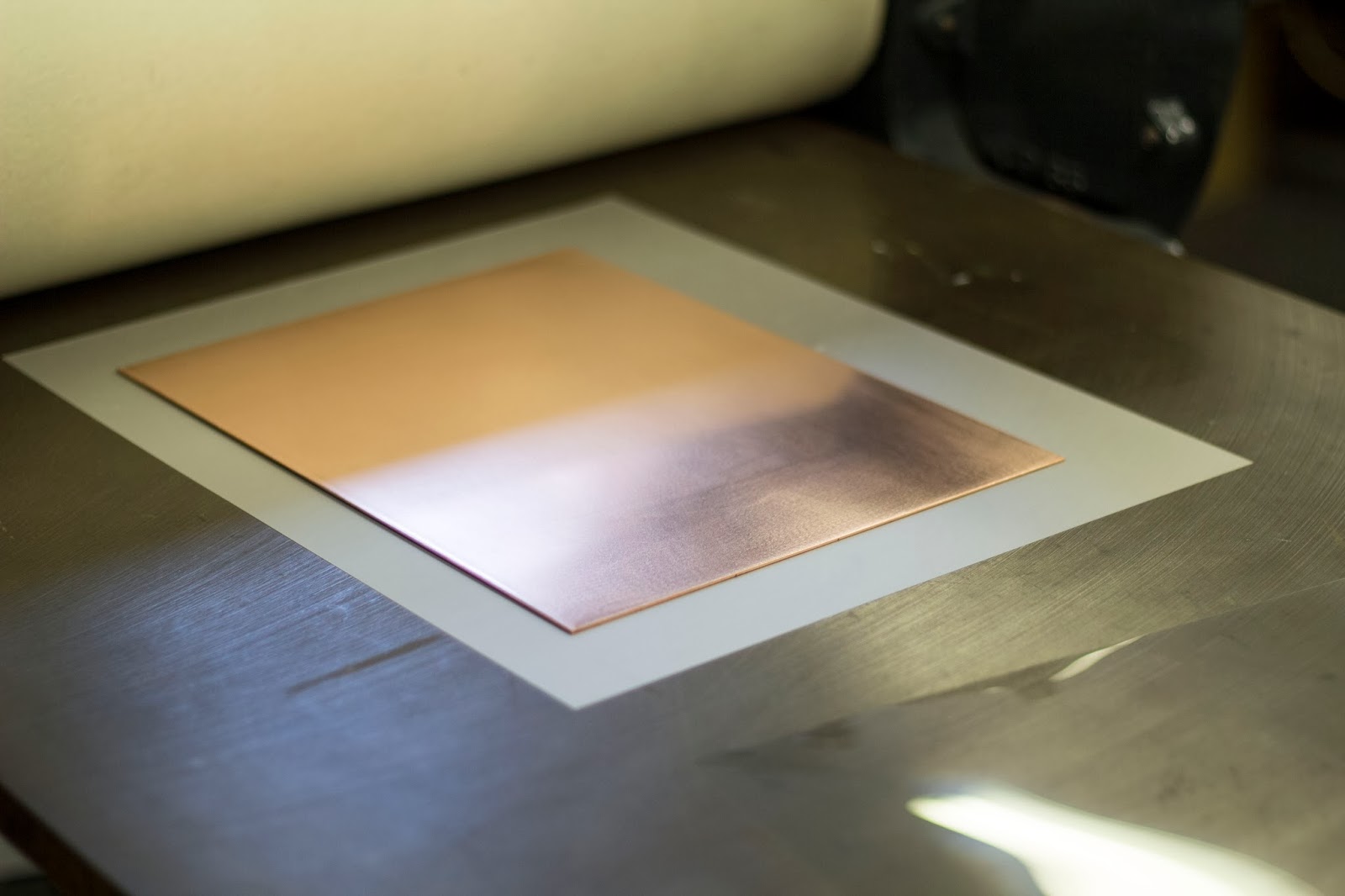

Finally, I had to make an embossing plate made out of copper which I would be able to ink up and press. I did this by taking advantage of the process of etching but let it eat away at my copper for a lot longer.

The next day I took it out of the stripper and my plate was complete.

I used a scalpel to cut out the panels to mask it off and placed this in the gaps when inking my plate up. This ended with many disasters and a lot of frustration. I never ended up managing to create a perfect book cover as the ink was too thick and sticky that it would take my masking away. Different methods of sticking were used until I ran out of time.

The next day when everything dried I began binding, I chose to two-up saddle stitch each book in the same way to feel more hand-made and keep consistent with the rest of the project.

The final part was to create the packaging. This had to be laser-cut, sanded and then bound.

To begin with, the spine I had made was too big so I ripped it out and re-did it.

Leave your comment